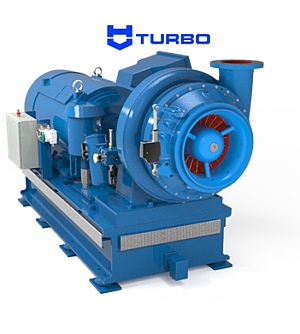

KA Series

Single-stage radial blower with advanced mechanical and aerodynamic design and the most modern control system.

Usage

- Municipal and industrial sewage treatment plants

- Flue gas desulphurization

- Fermentation and production of enzymes

- Production of pulp and paper

- Sulfur Recovery (SRU)

- Air “lubrication” system

The HV-TURBO blower of the KA series has an advanced mechanical and aerodynamic design and the most modern control system.

The compression part and the integrated gearbox have been developed and evolved based on over 30 years of manufacturing experience, creating the most efficient blower on the market today. Each personalized KA series blower is specially tailored to the specific requirements of the recipient, while consuming much less energy than other compressor / blower designs. High-quality blower components and compliance with all technical standards ensure long-term reliability and minimal maintenance. The actual efficiency of the blower is as in the design. Each of our carefully designed blowers is adapted to the installation conditions, while consuming the minimum power required. The blowers may be controlled by variable guide vanes, variable diffusers, or both. The choice between the different available control systems is based on the varying demand for flow rate, discharge pressure and possible ambient conditions. The KA turbocharger is also available in the BaseLINE version, which is dedicated to wastewater treatment.

BaseLINE for sewage treatment plants, Tailor-made wastewater solution, flue gas desulfurization (FGD), enzyme fermentation and production, pulp and paper processes, furnaces and smelters, sulfur recovery (SRU) and more.

- The highest efficiency is automatically and continuously maintained throughout the entire control range, as well as selected according to the ambient temperature and pressure ranges in which the compressors are most often operated.

- Variable flow due to variable impeller geometry, variable inlet vanes or a combination of both - Dual Point Control ™.

- Compact design

- Flow and pressure range from 1,000 to 125,000 (m3 / h). Pressure difference up to 2.5 bar (g). The HV-TURBO® range of compressors for municipal and industrial applications includes various sizes. All compressors in this series are a complete package consisting of an integrated gearbox, clutch, electric motor and lubrication system, all mounted on a common base frame.

Why HV-Turbo blowers?

Our advanced test platform, which includes mechanical and functional simulation as well as performance simulation, ensures full verification that all technical requirements have been met before the blower leaves the factory

In our experience there is no substitute for local support so we have local teams ready to help you around the world. The KA compressor is part of the TURBLEX brand in America and HV-TURBO in the rest of the world.

Our professional team of designers and engineers is the key to our clients' success. With exceptional skills and services, our dedicated R&D team members are

masters in developing efficient blowers and creating solutions that complement the requirements of our customer project team. Our design and engineering experience

covers soft and hardware engineering and mechanical engineering.

KA BaseLINE series: dedicated solution for wastewater treatment plants

The KA BaseLINE HV-Turbo® blower is built according to the same, well-known, highly developed and reliable technology as all the compressors / blowers in our portfolio, but adapted to installations with a capacity of 1,000 – 16,000 m3 / h, dedicated to wastewater treatment plants.

The HV-Turbo® blower of the KA BaseLINE series is an integrated, single-stage centrifugal blower equipped with oil-lubricated ceramic ball bearings. The blower is equipped with a fourth generation rotor with backward curved blades according to the desired adjustment, made of a solid, forged piece of high-grade aluminum alloy with an optimal weight / strength ratio. Over the past 40 years, the oil lubricated bearing concept has proven to be the most reliable and cost effective solution in this industry. Several thousand of our blowers work after more than 25 years of use. The technology behind the BaseLINE series – making them the most efficient and reliable in the industry – is simple.

The rotor and gearbox can be fully adapted to meet the specifications of each plant, thus eliminating the risk of oversizing.

The BaseLINE blower is equipped with the unique Dual Point ControlTM system with inlet and outlet blades for high operating efficiency from 100% to 40% reduction in capacity. Dual Point ControlTM allows the user to adjust and operate the blower in areas of maximum efficiency and minimum power consumption over a wide adjustment range.

With the S7-1200 PLC, the Local Control Panel (LCP) becomes the intelligent KA blower control center. Moreover, in combination with Dual Point ControlTM and compressor instrumentation, the LCP provides an excellent automation concept that keeps efficiency at a consistently high level.

Application areas:

Mainly sewage treatment.

Flow and pressure range:

Flow and pressure range from 1,000 to 16,000 m3 / h with differential pressures up to 1 bar (g).